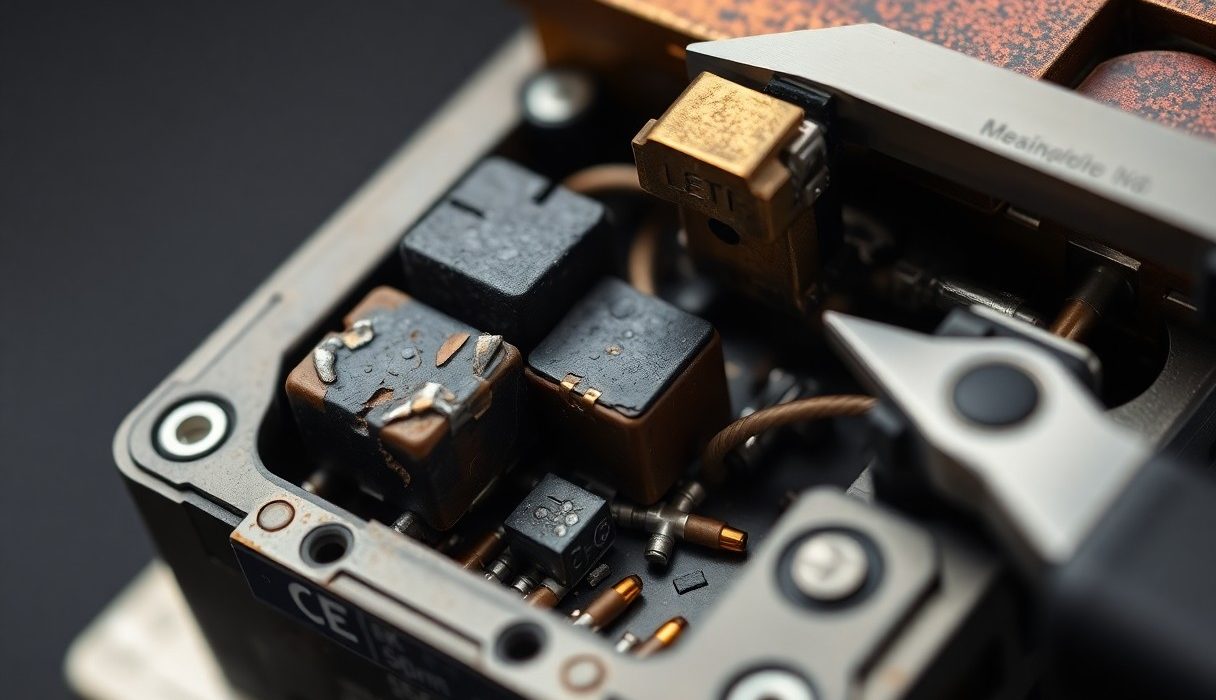

Mechanical wear in traditional relays wears down contacts and springs over cycles, so you experience rising contact resistance, bounce, and unpredictable switching; contact erosion and arcing accelerate degradation and can produce heat, sparks, and fire or short circuits. Because you rely on consistent operation, this leads to downtime and safety risk, while regular inspection, contact cleaning, or switching to solid-state options can significantly extend your system’s service life.

Types of Mechanical Wear

Different mechanisms strip material from contacts and springs in ways that compound over time; in many relay applications you will see one dominant mode that then accelerates others. Field data shows that a relay with a nominal mechanical rating of 100,000 cycles can drop to an effective electrical life of 1,000-10,000 cycles under heavy arcing or contaminated environments, so you need to assess which wear mode will most rapidly degrade your device.

Your maintenance and design choices influence which wear mode dominates: sealing and filtration reduce particle-driven loss, contact material selection changes micromelting tendencies, and contact protection circuits reduce arc-related damage. The common categories you should consider are listed below:

- Abrasive wear

- Adhesive wear

- Fretting wear

- Erosive wear

- Contact fatigue

| Wear type | Typical effect on relay contacts |

| Abrasive wear | Particle-driven removal of contact metal, surface roughening, loss of plating (particles 1-100 µm have outsized impact) |

| Adhesive wear | Micro-welding and material transfer during high-contact-pressure or arcing events, leads to increased resistance and occasional welding |

| Fretting wear | Oscillatory micro-motion causing oxide formation and pitting, common in vibrating environments and reduces contact reliability |

| Erosive wear | Arc-driven melting/splashing and gas/flow-borne erosion that pits surfaces and embeds oxides |

| Contact fatigue | Crack initiation and propagation from repeated stress cycles, leading to sudden loss of spring force or contact integrity |

Abrasive Wear

When abrasive particles enter the contact interface, they act like miniature files: you will see material removal measured in micrometers per thousand operations depending on particle hardness and concentration. For example, in switchgear exposed to industrial dust (silica and metal particulates), wear rates equivalent to 0.5-5 µm per 1,000 cycles have been recorded, which can remove thin silver plating within a few thousand actuations and expose base metal to accelerated corrosion.

Mitigation for abrasive wear involves both environmental control and materials choices: you should specify seals, positive-pressure enclosures, or filters for dusty installations, and prefer harder contact substrates or sacrificial platings (for instance, silver over nickel with a controlled thickness of 5-10 µm). Increasing contact force reduces the chance of particle embedding but raises wear from sliding, so you must balance contact pressure against expected particulate load.

Adhesive Wear

Adhesive wear in relays is driven by localized high-pressure contacts and transient arcing that produce micro-welds; you will notice material transfer between mating surfaces and sudden jumps in contact resistance when this happens. In practical terms, switching currents of 1-10 A at mains voltages can produce sufficient thermal and mechanical energy during make/break events to weld soft contacts-case studies on silver and silver-alloy contacts show observable material transfer after a few thousand heavy-load operations.

Once micro-welding begins, subsequent operations can tear off transferred material, producing debris that aggravates abrasive wear and creating a positive feedback loop; contact resistance can increase from milliohms to ohms in a small number of fault cycles, often resulting in functional failure or a persistent welded contact. You should evaluate snubber networks, arc suppression, and contact material like gold for low-current signals or silver alloys for higher currents to reduce welding tendency.

More detailed protective measures include the use of contact shaping to minimize localized pressures, spot-welding-resistant alloys, and diagnostic monitoring: ultrasonic or contact-resistance checks after 10,000 switching events in harsh duty profiles will catch adhesive degradation before catastrophic welding impairs the circuit. Thou, schedule inspection and protective upgrades based on the specific current, voltage, and environmental profile of your relay application.

Factors Contributing to Mechanical Wear

You’ll see mechanical wear driven by a mix of cyclical stressors: repeated contact impact and rebound (contact bounce), micro-arcing during make/break events, and gradual surface abrasion from particulates and corrosion products. Manufacturers often rate relays for on the order of 10^5-10^7 mechanical cycles, but that number collapses quickly when you add elevated currents, higher contact forces, or contaminated atmospheres; arc erosion can remove tens to hundreds of micrometers of contact material over thousands of switching events, and spring fatigue reduces contact force by noticeable percentages after a few hundred thousand cycles.

- Contact bounce

- Arc erosion

- Friction and abrasion

- Fatigue (spring and metal)

- Corrosion and contamination

Different combinations of those factors change the dominant wear mechanism: for example, in signal relays fretting corrosion from micro-motion is often the limiter, whereas in power relays thermal and arc-driven pitting dominate. Any time you combine high humidity, abrasive particulates and frequent switching you can expect wear rates to increase by an order of magnitude.

Operating Environment

When you place a relay in an industrial panel or an automotive harness, ambient conditions immediately alter wear dynamics: temperatures from -40°C to +85°C change material ductility and oxide formation rates, while relative humidity above ~70% accelerates corrosive attack on exposed contacts. Vibration-measured in g’s-causes micro-motion and contact bounce; a relay exposed to sustained vibration levels of a few g during operation will see contact life drop substantially because repeated impacts both abrade surfaces and reduce effective contact force.

Specific environments produce predictable failure modes: salt spray or sulfur-containing atmospheres induce sulfide or chloride films that increase contact resistance and promote arcing at lower currents, and dust-laden environments introduce abrasive particles that score contact surfaces by tens of micrometers per thousand cycles. In automotive testing, relays subjected to 85°C/95% RH soak and 10^5 electrical cycles often fail earlier than identical relays tested at room conditions, highlighting how environmental stress multiplies mechanical wear.

Material Composition

Contact metal choice governs the trade-off between conductivity, hardness and oxidation resistance: silver offers the lowest resistivity (≈1.59 µΩ·cm) and excellent conductivity but oxidizes and pits under arcing, while gold resists oxidation and maintains low contact resistance for low-current signals but is soft and can wear off when subjected to high arcing energy. You need to match materials to the switching regime-signal-level contacts often use gold plating of thin layers for reliability, whereas power contacts use silver alloys or oxide-dispersed composites to resist arc erosion.

Alloying and plating thicknesses matter: relays rated for >1 A typically use silver-cadmium oxide or silver-tin oxide composites that tolerate arcing better, and manufacturers specify mechanical endurance in the range of 10^5-10^7 cycles depending on the contact material and load. When you switch currents in the ampere range, expect micro-welds and pitting to form; for example, repeated 10 A switching events can create measurable craters on silver contacts within thousands of operations, increasing contact resistance from single-digit milliohms to tens or hundreds of milliohms.

More detailed material choices include silver-nickel and silver-copper alloys for moderate power applications, and thin gold flashes (commonly on the order of 0.1-2 µm) applied over a more robust substrate for low-voltage contacts to prevent fretting corrosion; you should also note that oxide-dispersed composites reduce material transfer and welding but can raise initial contact resistance slightly, so the selection is always a balance between arc resistance, wear rate, and acceptable contact resistance for your application.

Tips for Minimizing Wear in Relays

Reduce switching stress by matching relay selection and circuit protection to the load: for AC inductive loads use RC snubbers or MOVs to limit contact arcing, and for DC loads add inrush limiting (NTC or soft-start) to reduce contact erosion. Keep switching frequency within the relay’s rated range – many general-purpose electromechanical relays are specified for roughly 10^5-10^7 mechanical operations; if your application needs >10^7 cycles, consider reed relays or solid-state options. When you design panels, specify contact materials (silver-alloy for high-current, gold for low-level signals) and ensure coil suppression (diode or RC) is included to prevent excessive coil-driven rebound.

- Use RC snubbers or MOVs for inductive loads to limit arcing

- Derate contact current by 25-50% for frequent switching or inductive loads

- Choose relays rated for the required cycle life and environment (IP rating, temperature)

- Apply contact protection (gold plating, gas-filled relays) for low-voltage, low-current switching

Regular Maintenance

Establish inspection intervals based on duty cycle: for heavy industrial duty inspect visually and measure contact resistance every 3-6 months or after ~10^5 switching events; for light commercial loads quarterly or every 6-12 months is often sufficient. Use a micro-ohmmeter to log contact resistance – typical good relay contacts read in the low milliohm range (single- to double-digit mΩ); a rising trend of >50-100% indicates pitting or increased oxide and suggests replacement or cleaning.

When you service relays, look for pitting, discoloration, spring tension loss, and coil insulation degradation; document replacements and any load anomalies such as repeated arcing or chattering. For sealed relays avoid opening housings; instead swap with spares and send suspect units for lab life testing – field data from a PLC line showed swapping relays at 80% of rated cycles reduced unexpected downtime by 60% over 12 months.

Selecting Suitable Components

Match contact material and relay type to the switching profile: choose silver-alloy contacts for currents above a few amps and gold-plated contacts for microvolt/microamp signal switching to prevent fretting corrosion. If you need high-frequency switching or very long cycle life, specify reed relays (life >10^8 cycles in many datasheets) or solid-state relays to eliminate mechanical wear entirely for switching rates above 1 Hz sustained.

Factor in inrush and inductive characteristics: for motors and capacitive loads select relays with higher make/break ratings and consider pre-charge circuits or soft-start to limit peak stress on contacts. You should also require datasheet parameters for bounce time (typical 1-5 ms), contact resistance, and rated switching current under inductive conditions when evaluating vendors.

Specify a safety margin: pick relays with at least 25-50% headroom on continuous and inrush currents, require vendors to provide electrical life curves at your application load, and prefer designs with proven field data in similar environments (for example, HVAC control panels with >100k cycles without replacement). Thou should schedule maintenance based on cycles and load profile rather than calendar alone.

Pros and Cons of Traditional Relays

| Advantages | Disadvantages |

|---|---|

| Simple, low-cost construction | Mechanical wear shortens service life |

| Galvanic isolation between coil and contacts | Contact arcing and pitting under load |

| High peak current capability (power relays often handle tens to hundreds of amps) | Relatively slow switching: typically 5-20 ms |

| Very low closed-circuit resistance (milliohm range) when contacts are healthy | Contact bounce (1-5 ms) can generate EMI and false triggers |

| Audible/visual indication (the click) aids diagnostics | Limited cycle life – commonly around 10^5-10^7 operations depending on load |

| Wide voltage and load-type flexibility (AC/DC, inductive/resistive) | Sensitivity to shock, vibration and contamination |

| Repairable and field-replaceable in many designs | Requires occasional maintenance or contact replacement |

| Cost-effective for low-frequency switching and power applications | Poor fit for high-frequency or high-cycle-count applications |

Advantages

In practical systems you often choose relays because they give true electrical isolation and straightforward protection boundaries between control and power circuits; this is why relays remain common in industrial panels and automotive systems. For example, a standard automotive SPDT relay rated at 30 A costs a few dollars and can switch starter circuits reliably, while power relays used in HVAC or motor controllers can handle hundreds of amps for short durations with minimal on-state loss.

You also gain diagnostic simplicity and field serviceability: the audible click and visible contact arrangement let you verify operation without special equipment, and worn contacts can often be replaced without swapping the whole module. When you need low on-resistance and the ability to tolerate short overloads, a mechanical contact still outperforms many solid-state alternatives in raw current handling and conduction loss.

Disadvantages

Mechanical motion produces wear you must plan for: repeated strike energy creates contact pitting, increases contact resistance, and eventually leads to failure modes such as intermittent connection or contact welding under heavy load. In field cases-PLC outputs switching small motors or solenoids-operators commonly see degraded contacts after tens of thousands of operations; under inductive loads that number can drop dramatically unless suppression is used.

The switching dynamics introduce other problems you will face in designs that require precision or speed: contact bounce (typically 1-5 ms) causes multiple make/break events per operation, producing EMI and potential logic misreads, and the overall switching time (usually 5-20 ms) prevents use in high-frequency applications. Vibration and contamination further accelerate degradation, meaning that in harsh environments your maintenance intervals must be shorter.

Mitigation techniques such as arc suppression circuits, contact material selection (e.g., silver alloys, ruthenium coatings), and using appropriately rated contactors extend life, but they cannot eliminate wear entirely; when you need millions of cycles, solid-state options or hybrid approaches are usually the only practical solution.

Step-by-Step Guide to Enhancing Relay Lifespan

Action Plan

| Step | Details / Example Values |

| Characterize the load | Measure steady-state and inrush currents; log inductive kick voltage. Typical motor inrush can be 5-10× running current, while solenoid inrush is often 3-6×. |

| Derate contacts | Specify relays at 50-70% of rated continuous current for inductive or continuous duty. For pulsed loads, keep peak current <3× rated if possible. |

| Use contact protection | For DC inductive loads use a flyback diode (fast recovery for high-speed switching). For AC or mixed loads use RC snubber (0.01-0.1µF with 100-1kΩ) or a TVS/surge suppressor sized to clamp above nominal voltage. |

| Choose appropriate contact material | AgSnO2 or AgNi for general use; AgCdO historically good for arcing but restricted by RoHS. Specify material when switching high-voltage or low-current signals. |

| Adopt smarter switching techniques | Implement zero-cross switching for AC resistive loads, soft-start/precharge for capacitive/inrush-heavy systems, and make-before-break for critical low-voltage signals when needed. |

| Mechanical and environmental controls | Use sealed or hermetic relays in dusty or corrosive atmospheres. Limit ambient temperature to relay spec; every 10°C above rated can halve mechanical life in many electromechanical devices. |

| Maintenance & monitoring | Track contact resistance and operation count. Replace when contact resistance rises by a factor of 3-5 or after reaching the manufacturer’s electrical life rating (often 10^4-10^7 operations depending on load). |

Best Practices

You should quantify both steady and transient conditions before selecting a relay: measure RMS and peak currents, switching frequency, and expected duty cycle. Manufacturers often specify electrical life at a particular load-for example, a relay rated for 10 A resistive might be listed at 100,000 cycles resistive but only 10,000 cycles inductive; use those numbers to size replacements and set end-of-life alerts.

Wherever possible, add external suppression tailored to the load: a flyback diode for DC coils, an RC snubber (0.01µF/220Ω is common for small AC inductive loads) for AC, and a TVS for high-energy transients. You should also derate contacts to 50-70% for continuous or inductive duty and choose contact metallurgy suited to arcing environments (AgSnO2 for general-purpose; specify alternatives for RoHS-constrained designs).

Common Pitfalls to Avoid

Failing to measure inrush and only using steady-state ratings is a frequent mistake; it often causes contact pitting and early welding. You must not assume a relay’s resistive rating applies unchanged to inductive or capacitive loads-test or use manufacturer correction factors. In one field case, a panel using relays rated 16 A resistive failed within 2,000 cycles when repeatedly switching a 12 A motor with 8× inrush because the design ignored inrush derating.

Another common error is inappropriate suppression: using a slow axial diode on a high-speed DC switching line can prolong flyback decay and heat contacts, while undersized TVS devices simply blow. You should match suppression to switching speed and energy-choose fast, low-impedance clamps for high dv/dt environments, and RC snubbers where energy is lower but repetitive.

Additionally, environmental neglect is costly: unsealed relays in humid or corrosive atmospheres can develop oxide layers that raise contact resistance to >100 mΩ, degrading performance; inspect and replace units when resistance drifts beyond 3-5× the baseline or when operation count approaches the electrical life rating.

Alternatives to Traditional Relays

You can dramatically reduce mechanical failure by moving to non-mechanical switching or to mixed designs that isolate contacts from arcing. Mechanical relays typically survive on the order of 10^5-10^7 operations, whereas solid-state devices commonly exceed 10^7-10^9 cycles under rated conditions; that gap alone explains why industries with high duty cycles – telecom switching, automated test, and electric vehicle contactors – choose alternatives. Keep in mind that each option brings trade-offs in thermal management, off-state leakage, and cost-per-channel, so your selection depends on whether you prioritize lifetime, power efficiency, or fail-safe isolation.

For many real-world systems you’ll find a hybrid approach (or careful SSR selection) gives the best balance: SSRs remove arcing and extend life, but produce heat and small leakage currents that can upset low-current sensing circuits; hybrids combine the low on-resistance of a contact with semiconductor-driven arc suppression. In practice, replacing a mechanical relay in a motor starter often requires upgrading control logic, adding snubbers or inrush-rated SSRs, and planning for heat sinks – otherwise you trade contact wear for thermal failure.

Solid-State Relays

You should evaluate SSR families by topology: TRIAC/thyristor SSRs are inexpensive and ideal for resistive AC loads with zero-cross switching, while MOSFET- or IGBT-based SSRs give fast, bipolar switching and much lower on-state losses for DC and high-frequency AC. MOSFET SSRs can switch in the microsecond range (<50 µs) and, when properly cooled, sustain millions to billions of operations; TRIAC SSRs, by contrast, typically switch only at zero-cross and are unsuitable for phase-angle dimming or precise PWM control. Off-state leakage for many SSRs sits in the 1-10 mA range, which can be dangerous for low-current circuits or cause parasitic loading in battery systems.

When you spec an SSR, pay attention to thermal derating: a device with 0.1 Ω effective on-resistance at 10 A will dissipate ~10 W and almost always needs a heatsink or chassis mounting. In one field example, retrofitting an HVAC compressor controller with a MOSFET SSR eliminated contact welding and extended service life, but required doubling the control cabinet ventilation to keep junction temperatures below rated limits; that trade – improved longevity versus added cooling – is common across SSR deployments.

Hybrid Solutions

Hybrid relays pair semiconductor switches with mechanical contacts so you get the arc-free switching of SSRs and the near-zero on-resistance of metal contacts during steady-state conduction. Typical operating sequences have the semiconductor close first to handle the transient and absorb arc energy, then the contact closes to take over continuous current; afterwards the semiconductor opens, leaving the contact carrying the load with minimal wear. In many bench tests hybrids reduce measurable contact erosion by more than 90%, extending maintenance intervals from months to years in high-cycle installations.

You must still design for complexity: hybrids require sequencing logic, interlocks to prevent simultaneous conduction that causes shoot-through, and diagnostic sensing to detect semiconductor or contact failures. Applications that benefit most include battery disconnects, EV charge relays, and critical power transfer switches where you want both low conduction loss and long operational life. Cost per channel is higher than a plain relay, but total lifecycle cost often falls due to fewer replacements and less downtime.

Further details to consider: hybrids commonly use MOSFET stacks for the semiconductor stage to minimize voltage drop and to handle inrush (motors often draw 5-10× running current), while the contact stage is specified for continuous RMS current with a safety margin. You should include temperature and failure-mode monitoring (for example, current sensing that detects a semiconductor short) because a failed semiconductor can create a hazardous fault condition if not detected and isolated quickly.

Final Words

Following this, you should understand that traditional relays rely on mechanical motion and contact closure, so friction, spring fatigue, and repeated impact continually wear components. Each switching event produces arcing, contact pitting, material transfer, and surface oxidation that increase contact resistance and heat generation, which degrade performance and consistency over time and reduce your relay’s reliable cycle life.

You can limit wear by selecting durable contact materials, controlling inrush and switching currents, adding suppression circuits, and scheduling replacements, but mechanical fatigue and contact erosion remain inherent failure modes; you therefore need to plan maintenance intervals or choose solid‑state alternatives when your application demands long life or extremely high cycle counts.